It was a long time ago, but I still remember basic training. The first day, we were issued our M-16s. Then we were told we had to clean them. I was fortunate, in that I had owned guns before and had an idea of how to clean one. But comparing what my dad expected of me, when I cleaned a gun, and what my drill sergeant expected of me was like comparing a child’s ring from the toy department in a dollar store to Jacqueline Kennedy’s engagement ring. They were nothing alike.

Looking back, it’s easy to say that the Army and Marines obsess with soldiers cleaning their guns. The basic rule of thumb is that you clean your gun first, then you can think about taking care of yourself; you know, little things like getting something to eat or some rest.

There’s a good reason for that, especially in the military; dirt can cause malfunctions in any firearm, and malfunctions of any sort can end up costing lives. That’s something we never want to see happen. Even though military firearms are designed and tested so that they can be buried in the mud and still expected to shoot; it’s widely accepted that proper cleaning and lubrication is essential to ensuring their operation.

But what about you and I? Do we need to be quite as stringent about our gun care routine?

I know people who clean their firearms religiously, each and every time they fire them. I also know people who never seem to clean them. Both have their reasons and at least to some extent, both are right. But they are right in different ways. The truth is, the average privately owned firearm isn’t shot enough for carbon buildup to cause much of a problem. That’s especially true if the owner regularly oils the gun. Oil will help to break up the carbon buildup on parts, reducing its ability to cause misfires. However, that suspended carbon can cause excessive wear, especially as the oil starts to dry up, redepositing the carbon back on moving parts.

The truth is, the average privately owned firearm isn’t shot enough for carbon buildup to cause much of a problem. That’s especially true if the owner regularly oils the gun. Oil will help to break up the carbon buildup on parts, reducing its ability to cause misfires. However, that suspended carbon can cause excessive wear, especially as the oil starts to dry up, redepositing the carbon back on moving parts.

But there’s another issue for us as preppers. That is that our reason for owning firearms in the first place (besides shooting being fun) is that if we ever find ourselves in a survival situation, we expect to need those guns to help keep us alive. That could mean for hunting, but it is more likely to mean to protect us from the two-legged predators in the world.

With that in mind, our need to ensure that our firearms don’t misfire is just as important as it is for the military. So it only makes sense that we take as good a care of our AR-15s and other guns, as I learned to take care of my M-16 in the Army.

One Important thing to Know

There is one important thing you should know about your particular AR-15, which can affect cleaning. It’s not that you would actually clean your AR-15 differently, but it could affect how often you clean it. Originally, the M-16 and AR-15 were designed with a gas impingement system. What this means is that there is a gas tube that goes from the front sight post to the receiver, where it interfaces with the bolt carrier, cycling the action for the automatic and semi-automatic firing of the gun.

This gas tube is a lot of the reason why the AR-15 is a “dirty gun,” which needs to be cleaned a lot. The carbon-rich gas being carried via this tube tends to dirty up the bolt carrier and the upper receiver. While there is enough slop in the design to accommodate quite a bit of that carbon, it can cause extractor and firing pin problems.

Some models of AR-15s use a newer and more expensive piston impingement system, instead of this gas impingement system. In this case, the receiver and bolt carrier of the gun will stay cleaner, reducing the frequency which the gun needs to be cleaned. The AR-15 depicted above is like this. One way you can tell, although it is not a sure sign, is that it does not have a high front sight post.

Related: The AK-47 vs AR-15: Which Rifle is Better When SHTF?

Field Stripping an AR-15

By definition, field stripping of any gun consists of taking it as far apart as you can, without the use of tools. Manufacturers make their firearms in such a way, so that the parts which need to be cleaned and lubed are readily exposed by removing the slide or splitting the receiver apart. In the case of the AR-15, like the M-16 and M-4, field stripping consists of splitting the upper and lower receiver apart, just by pulling the takedown pin out to its stop.

It should be noted that the original M-16, which the AR-15 was styled after, required a bit more to field strip it. That’s because the original design called for plastic and metal foregrips, which locked into the front sight post and a spring-loaded retaining ring just forward of the receiver.

If your AR-15 is styled after this, rather than having a quad rail on it, removing the grips is not absolutely necessary for cleaning an AR-15, as all the functional parts are accessible by opening the receiver. All you can access by removing the forestock is the outside of the barrel.

With the takedown pin removed and the receiver open, the bolt carrier and charging handle can be removed from the upper receiver. The two pieces come out together, although it is possible to remove the bolt carrier, without having to remove the charging handle. However, the charging handle and the slot that it sits in should be cleaned as well.

The bolt carrier consists of four parts which need to be disassembled for cleaning. This is very important, as the parts which are most likely to jam are the firing pin and extractor, both of which are in the bolt carrier.

To disassemble the bolt carrier, first remove the firing pin retaining pin. This is a cotter pin that goes into the bolt carrier from the side. Any sharp tool can be inserted into the head of the cotter pin to remove it. With the retaining pin removed, the firing pin can be removed by the simple expediency of turning the bolt carrier vertical, with the bolt face upwards and allowing gravity to cause the firing pin to fall out.

There is also a cam pin inserted into the bolt carrier. This has a rectangular head, which is hidden under the gas feed tube. Turn the head of the cam pin 90 degrees and slide it to the end of the slot, so that the head is out from under the gas feed tube. Remove it from the bolt carrier.

With the cam pin removed, the bolt can now be removed from the bolt carrier. It might be a snug fit, but should come out with nothing more than your fingers.

The AR-15 is now fully field stripped and ready for cleaning.

Cleaning Equipment and Supplies

It is possible to buy a cleaning rod which will just allow you to clean your AR-15, as well as buying the other items separately. However, it is easier and cheaper in the long run to buy a universal cleaning kit, something like shown below. While you can spend considerably more, this kit sells for under $20.

As you can see in the photo, the kit will contain a full-length cleaning rod, which allows cleaning of rifles, as well as pistols. It will also contain a series of patch holders, bronze brushes and “mops” for different caliber firearms, as well as a toothbrush and other tools.

You will also need gun cleaning solvent, gun oil and patches of the appropriate size for the caliber of gun you want to clean. The two most popular brands of gun cleaning solvent are Break-Free and Hoppe’s Number 9. Patches come in a variety of sizes and will work for a variety of calibers which are of similar overall size, but you can’t use a patch which is too big to fit into the bore or one which is too small to make good contact with the walls of the barrel, when you are pulling it through.

The Break Free product shown in the image above includes a lubricant as well, so if you use it and don’t lubricate your gun as a separate step, it will still have some lubricant. This product comes in a spray can, with a small tube (red line on the right side of the can), making it easy to apply the solvent directly to the part of the gun that you want.

Related: DIY Gun Solvent

Cleaning the Bolt & Carrier

For most rifles, the most important part of cleaning is the barrel, but not for the AR-15. Unless you stuck the muzzle of the rifle down into the mud and have mud packed into the barrel, the most important part of cleaning an AR-15 is to clean the bolt and bolt carrier. Most malfunctions happen in this assembly.

With the individual pieces of the bolt and carrier disassembled, they can be soaked in cleaning solvent or cleaned with solvent and a rag or solvent and cleaning patches. All carbon needs to be removed from the various parts. A toothbrush can be helpful in removing carbon from the holes and crevices in the various parts. The carbon is easily recognizable in that it is a flat-midnight black color, whereas the parts of the gun might be black, but they are not as flat or as black as the carbon.

The charging handle, which you took out along with the bolt carrier should be cleaned in the same way as the bolt parts, using cleaning solvent and rags. It is not as critical as the bolt and carrier.

Check the extractor, mounted in the side of the bolt, for freedom of movement. Carbon buildup behind the extractor can limit this movement, causing problems with the operation of the extractor. If your extractor does not move freely, the extractor should be removed from the bolt and the area behind it cleaned.

To remove the extractor, push on the extractor pin with a small pin punch. It can help to push the extractor in, towards the body of the bolt, while doing this. That will take some of the pressure off of the pin, allowing it freedom of movement. Be sure not to lose the spring and pin, located on the underside of the extractor. It might also have an O-ring around the spring, although this is not original.

Clean the area under the extractor out with cleaning solvent and a toothbrush, then reassemble the bolt by setting the extractor in place, pushing down on it and reinserting the pin.

Once the various parts of the bolt receiver are cleaned, they can be reassembled by reversing the steps used to take the bolt receiver apart.

Cleaning the Barrel & Upper Receiver

Cleaning the barrel is important from the viewpoint of preventing the barrel from becoming plugged. While it is rare for a barrel to become fully plugged, buildup of carbon and residue in the barrel can increase the friction between the bullet and the barrel, slowing the muzzle velocity of the round slightly. At the same time, this can increase the wear on the rifling in the barrel.

Cleaning of the barrel was even more critical during the time of black powder firearms, as the burnt residue from the black powder was corrosive to metal. However, modern “smokeless powder” is not corrosive.

Barrel cleaning is accomplished with a cleaning rod, the various tips for the rod and cleaning solvent. The handle on the cleaning rod swivels, allowing the patch or brush attached to the rod to turn, following the rifling in the barrel.

There are several types of tips which can be attached to the cleaning rod as shown in the image on the right. Each has its own purpose, starting from the top:

-

Tips for gun cleaning rods Spear Pointed Jag – Not commonly used. These are made to work with a particular caliber of firearm. The jag is sized to allow only enough room between it and the barrel wall for the patch. This design ensures that the patch makes good contact with the barrel wall at all points. As such, these tips are ideal when you have a barrel that you need to ensure is extremely clean. They are also useful for oiling the barrel of a gun that is going to be put into storage.

- Patch Holder – This is the most common tip used on a cleaning rod. Patches are folded in half, diagonally, and slipped into the patch holder to be run through the barrel, either with cleaning solvent on them or plain.

- Brass Brush – As with the spear pointed jag, these are specific to a particular caliber of firearm. A universal gun cleaning kit will usually have several of them in different sizes. These are used for breaking up residue attached to the inside of the barrel, after solvent has been applied and before removing that residue with patches.

- Mop – These also come in different sizes, particular to the caliber. Some people use them in place of patches, as they provide more contact with the barrel, making cleaning faster. However, the mop has to be cleaned periodically, preferably after each use, making it more work to use a mop, than to use patches. The basic design harkens back to the mops used for cleaning the barrels of artillery pieces and muskets.

To clean the barrel of the AR-15, start with the patch holder and a clean patch. This first patch needs to be well-soaked in cleaning solvent, so that it can wet the inside of the barrel and any residue built up there. Run the patch through from the breach end (receiver end) and remove it from the rod before withdrawing the rod back down the barrel.

Replace the patch holder with the appropriate sized brush and brush the barrel through, several times, only brushing from the breach end to the muzzle end. This means that you will need to remove the brush from the rod after each pass through and reattach it after withdrawing the rod.

Place the patch holder back on the rod and run through several passes of patches, starting with a couple of passes with solvent-soaked patches and then following them with clean patches that don’t have any solvent, so as to mop up the dirty solvent. Typically, 10 to 15 patches are used to clean the barrel.

The actual number you use will depend on how dirty your barrel is. Keep cleaning the barrel, alternating solvent-soaked patches with a couple of dry ones, until your patches are coming out clean.

With the barrel clean, take a final clean patch and put oil on it, running it through the barrel to lubricate it. This is more to prevent the barrel from rusting, than it is to lubricate the bullets passing through it. The first bullet through the barrel will remove the oil.

Related: How to Make Shotgun Shells at Home? (With Pictures)

Clean the Upper Receiver

It is common for the inside of the upper receiver to be coated with carbon residue after firing the AR-15, especially in models which use gas impingement. While this carbon will not cause any problems, unless you get an extreme buildup, cleaning it out is a normal part of cleaning the AR-15.

Due to the shape of the upper receiver, it is difficult to get inside it with anything other than a toothbrush or a rag.

However, these simple tools are sufficient to clean out the carbon buildup. Use a cleaning solvent liberally to help with cleaning. You’ll want to clean all surfaces thoroughly, then wipe off excess cleaning solvent with a clean rag or cleaning patches.

Using a Bore Snake for Cleaning

An alternate method exists for cleaning a rifle’s barrel – the bore snake. This is a flexible device, which can combine the brush, cleaning and drying all in one, depending on the brand you buy.

Bore snakes are great for situations where you need something portable, as they are much easier to stuff in a pocket than a cleaning rod.

They are also useful when it is necessary to clean a gun from the muzzle end, rather than the breach end. Bore snakes are much less likely to damage the barrel in these cases.

Arguments rage up and down as to which is better, bore snakes or cleaning rods. The cleaning rod is more traditional and probably better when it is necessary to really scrub down a barrel. But if you’re looking for something that’s easy to work with and portable, the bore snake wins the debate.

Cleaning the Trigger Control Group

The trigger control group normally does not require any cleaning or maintenance, unless it has gotten dirt in it. Very little carbon buildup happens in the trigger control group, other than on the face of the hammer. However, carbon on the face of the hammer will not affect the operation of the gun.

If there is dust, lint or dirt inside the trigger control group, it is best removed with compressed air.

Simply blow it out. If this isn’t sufficient, spray some Break-Free solvent into the trigger control group and use a small paint brush to clean off the various parts. Unless you know what you are doing, it is not recommended to disassemble the trigger control group for cleaning.

While it is not recommended to disassemble the AR-15 trigger control group for cleaning, disassembly and reassembly is not difficult. If you have built your own AR-15, you will probably already be familiar with this process and may decide to disassemble the trigger control group for cleaning from time to time. Even so, this part of the gun rarely needs cleaning.

Cleaning the Outside of the Gun

The least important piece of the rifle to clean is the outside. Nevertheless, you shouldn’t ignore cleaning the outside. This is the part of the gun which is subject to the most wear. As such, with many guns it is also the part which is most likely to develop rust. That’s not a problem on an AR-15, but it is with your hunting rifle.

In normal circumstances, it is sufficient to wipe down the exterior of the gun with a soft cloth that has some cleaning solvent sprayed onto it. You can buy silicone impregnated cloths for this, which are ideal. However, when you get a new cloth, it will be so heavily soaked with silicone lubricant, that you’re going to have to wipe down the gun again, to get rid of the excess lubricant.

The nice thing about silicone lubricant is that it protects the gun extremely well. There are few solvents for silicone, so it won’t “wash off” your gun. It is also highly resistant to wear, allowing both the lubricant and the gun it is on to last for a long period of time. Finally, silicone is highly temperature resistant, so you don’t have to worry about it becoming ineffective from having your gun out in the heat or stored in the hot trunk of a car.

Related: Awesome Places to Hide Your Guns

Lubricating & Assembling the Gun

Lubrication of the AR-15, like many other firearms, must be accomplished while it is being assembled. The idea is to provide a thin coating of oil on any parts which rub against each other. This will reduce wear on these parts, helping your gun to last longer. It will also help maintain the gun’s accuracy, as parts will wear slower and are less likely to hang up on each other.

A high quality gun lubricant is recommended for lubricating any firearm. If you can, buy one with an applicator tip. If you can’t, then a syringe, with a blunt needle can be used as an applicator or a Q-tip. While some people complain about the risk of getting cotton fibers into the gun’s action, by using a Q-tip for applying oil, the risk is minimal.

Trigger Control Group

The trigger control group is not normally oiled on an AR-15. However, there are some users who do provide lubrication to these parts. If they do, it is a single drop of oil onto the interface between the disconnector and hammer. Another possible place for lubricating is the selector switch, especially if it is tight.

Please note that excessive lubrication of the trigger control group is just going to attract dust, which will stick to the lubrication. So you are better off with no lubrication, than with too much.

Buffer Tube

The buffer tube should be lubricated slightly, before the buffer and buffer spring is installed. This can be done with gun oil or white lithium grease.

In either case, apply a small amount of lubricant to the inside of the buffer tube, then use a finger to wipe the lubricant around the inside of the buffer tube, ensuring that you go 360 degrees with your finger, so as to not leave any lumps of lubricant or miss any parts.

It is not necessary to do this anywhere except at the opening, as the buffer spring will pick up the lubricant as it is installed, spreading it through the tube.

Bolt and Carrier

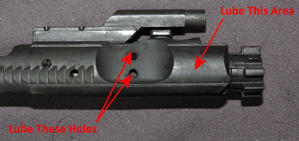

The bolt and carrier is the most important part to lubricate. To start, extend the bolt as far from the carrier as it will go, while assembled. Place a small bead of lubricant around the bolt, where it meets the bolt carrier. In addition, place one drop of oil in the opening for the cam pin and a small amount of oil in the gas escape holes. Run the bolt in and out to spread the lubricant around.

When properly lubricated, the bolt should slide from the inward position to the outward by holding the carrier and swinging it with a snapping of the wrist or rapid swing of the arm.

If it does not slide to the extended position, add more lubricant, work the bolt and try again.

The bolt carrier should be oiled on the outer surface, where it slides along inside the upper receiver.

This is especially important on the front part of the bolt carrier where most of the contact is made.

Charging Handle

The charging handle shaft (the part that goes inside the gun) should be lightly oiled on both the outside and inside, as both sides of the shaft interface with moving parts of the gun.

Takedown and Pivot Pins

After the bolt is installed in the receiver and the receiver is closed, you may want to put a small bead of lubricant around both the takedown and pivot pins, especially if they are difficult to move. Use minimal lubricant for this and wipe off the excess, so that it doesn’t cause dirt to stick to the outside of the firearm.

Assembling the Gun

To assemble the now-clean AR-15, start by verifying that the buffer spring is installed and the face of the buffer is past the face of the buffer detent.

Set the charging handle into the slot cut for it in the top of the upper receiver. Please note that you have to get the shaft of the charging handle about one inch inside of the upper receiver, before it will drop down into its slot. Do not push the charging handle all the way forward.

Place the gas tube on the bolt carrier into the underside of the charging handle, with the bolt face towards the rifle’s breach. Then slide both the bolt and the charging handle forward, until the charging handle locks into place. At this time, the lugs on the face of the bolt should be interlocked with those in the breach of the barrel as well.

If you have fully separated the two halves of the receiver, attach the front of them together at the pivot pin. Slide the pin home to hold them.

Swing the two halves of the receiver closed, rotating them on the pivot pin. Push the takedown pin in all the way to seat it.

The AR-15 is now properly cleaned and lubricated.

You may also like:

DIY Automatic Backyard Traps And Alarms For Looters And Intruders (Video)

Best & Worst States for Gun Owners

Well done and good article. I like to order the medical q tips. Very long handles and helps get in tight spots.you can also run clip as well. Soaking the rifle with clip the day before. Will draw out a lot of carbon that was buried in the metal.

Raven, I use the medical Q-tips too, for a lot of things. The long handle makes them great for getting into tight spaces.

Very detailed article, thanks!

Well written and informative article ! Thank You

Oh functions check the rifle is the Last step

Awesome thankyou

I actually tried an experiment where you remove the gas rings. The rifle ran fine but seemed sluggish. Never had a failure.

I use a one piece gas ring in all my builds. They are aggravating to get started in the groove and not as tight in the bolt carrier, but it keeps you from having to index the gas rings😁😁.

Don’t forget to stagger the gas rings before reassembly.

The only correction I would make is that smokeless powder is not corrosive. It was the primers that were corrosive. Corrosive primers were used in U.S. military ammunition up to about 1958. The one major exception was that M-1 carbine ammunition was all non-corrosive, even the stuff made in 1942.

Although some ComBloc military ammo is still made with corrosive primers, I don’t believe that 5.56 ammo even from ComBloc countries has corrosive primers. It always helps to make certain that they are non-corrosive. That is mainly because the U.S. market likes non-corrosive primers for obvious reasons.

Chuck – Thanks for your input. Some good information there, that I hadn’t included. Most shooters don’t think about corrosive powder and primers, but it is a very real thing. More often than not, it is taught that once we switched from black powder, corrosive powder was a thing of the past, even though that’s not totally true.

Perhaps I should add one more caveat: If you are firing steel cased ComBloc 5.56 or .223, be sure to do a very careful chamber cleaning. The lacquer on the steel cases has a tendency to add gum to the chamber and that will result in cases sticking in the chamber.

On the other hand, steel cases seem to run fine in AKs and SKSs.

They run fine because the AK and SKS tolerances are a lot more sloppy (on purpose…)

It’s evolution. Since they’ve been fed steel cases from their invention they’ve become well adapted to it. Sort of like those worms that live in 300 degree spouts in the ocean 🙂

I run poly wolf for training purposes. 1000 rounds is 200 shipped. I refuse to use tula just a garbage company with garbage ammo.

Either way you should be cleaning the rifle every time you shoot. Creates a habit and its keeping you and loved ones alive

I reload all my ammo including 223. Even with the best components the AR style rifle requires dedicated maintenance. This was a good article, Thanks!

I used to have Comic Books that were issued to troops and detailing on how to clean the M-16. I have lost them over the years.

Using Break Free CLP ……You must give it a VERY good HARD shake BEFORE you use it. (like spray paint for example) to get the best use out of it.

The little micro beads in he liquid ill an do separate,

I keep an original and complete Military Issue M-16 cleaning kit with a few extras in it such as a small bottle of Break Free/CLP and a pack of extra batteries for my optical site among other things, clipped to the sling….when I go to use the rifle I remove the pouch and clip it to my belt or lay it on the shooting bench Uses the ALICE Clips. Simple to use!

The AR platforms need MINIMAL lube. Anyone remember Mil-spec LSA??

IF you use too much lube it will attract sand and dust etc. So keep it minimal

There are new bolt and bolt carrier groups treated with nitride of some sort that are claimed not to need lubrication. Look them up if you want more info on them for now or when I get time will post a link or two on them.

All of that being said note that half-moon shape cut into the upper receiver……The armorers always would ding people on that.

The cure for that ..find a nice friendly Dental Tech and ask them if they could/would give you a set of dental piks….. they do wonders for cleaning most any weapon and scraping/removing carbon and other debris from tin places.

All of that being said firing Blanks as about or the worst thing to dirty up the gas system, If possible live fire a round or two and it would clean out the gas tube.

Originally the M-16 as designed for minimal or to be rarely cleaned……Lots of trouble when first adopted and issued and sent to SEA..The wrong propellant was used fouling the gas system and the chambers and barrels WERE NOT Hard Chromed.(Thank you Mcnamara).

Thanks for the well put together article. I am a gun dummy and appreciate info like this. It would be great if there were classes on things like this. Thanks again!