There is a multitude of reasons that we may find ourselves without power and need to move water from one place to another.

Whether you need to get water from a source to your home or have a basement full of water that needs relocating when the power is out you may be forced to use human power to move liquid.

Why Would Anyone Need To Build This?

Our power grid is very fragile. A Coronal Mass Ejection (CME) or Electro-Magnetic Pulse (EMP) would make short work of permanently disabling our power grid.

Since all the water that comes to our homes makes its way there through the magic of electricity, no power means no water.

It’s not only the cataclysmic scenarios that these styles of pumps come in handy, a large storm with the associated rains, storm surge, and power outages can leave you with a soggy basement and no way to extricate the water from it.

Building A PVC Hand Pump

With parts that you can either scrounge from around the home or purchase from your local hardware store, you can build a basic but very effective PVC water pump that operates much like a bicycle tire pump but will move water very effectively.

Related: 36 PVC DIY Projects for Your Homestead

There are two major components to this build.

First is the pump itself which is made from two sections of PVC pipe that nest one inside of the other which is what creates the suction.

Second is the two check valves that allow the water to flow only in the direction that you want it to. The check valves have a ¾” NPT thread so it will be easy to attach hoses or other piping to them.

Construction

One note before we begin is that you should build the entire pump complete without gluing it together first. This will allow you to confirm that everything works to your satisfaction after which you can disassemble and securely glue the components together upon reassembly.

In the associated photos with this article, you will note that I did not use any PVC cement or thread tape, but I recommend that you use both in your final builds.

First, I will cover the construction of the check valves as these are an integral component in the entire system.

Tools

You will need some tools to complete this build:

A reliable method of cutting the pipe to dimension

A reliable method of cutting the pipe to dimension- A hand drill or drill press

- PVC Cement

- Hand saw and files

- Sandpaper

- Petroleum Jelly

- Tape measure

Related: 26 Necessary Tools for Off-Grid Living

Check Valve Materials

- 4 – ¾” Slip on to ¾” MNPT PVC fittings.

- 2 – Pieces of ¾” PVC pipe cut to 2½”.

- 2 – Washers or O-rings that will fit inside of the fittings.

- 2 – Acrylic or rubber balls about ¾” in diameter (should fit inside the pipe with room for water to get around it but not so much that the ball will fall through the fitting or past the washer.

- 2 – Bradnails or other stiff thin metal.

Check Valve Instructions

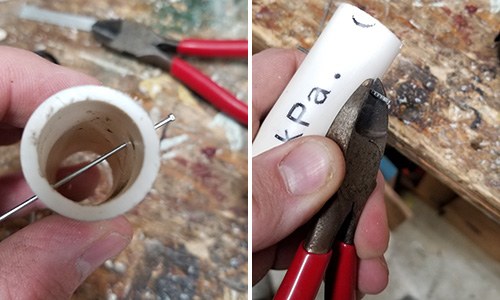

#1. Start by test fitting the washer or O-ring inside a fitting, then confirm that the ball will nest with the washer forming a good seal. The ball is what prevents water from flowing back through the fitting and the O-ring provides an additional seal.

#2. Next, you will need to drill a small hole through the pipe just far enough from the end that when the pipe is pressed into the fitting the hole is covered.

I measured the depth of the fitting and then placed the O-ring and ball into the fitting, I measured again from the top of the ball to the top edge of the fitting. Subtracting the two dimensions will give the minimum dimension that the hole can be from the edge of the pipe.

I measured the depth of the fitting and then placed the O-ring and ball into the fitting, I measured again from the top of the ball to the top edge of the fitting. Subtracting the two dimensions will give the minimum dimension that the hole can be from the edge of the pipe.

Add at least an eighth of an inch to this when marking out and drilling the hole. This will enable the ball to freely move but still be retained in the pipe.

#3. Insert a Brad Nail through the hole clipping the ends flush.

#3. Insert a Brad Nail through the hole clipping the ends flush.

#4. Assemble this end of the check valve by placing the washer in the fitting and the ball in the pipe. Then seat the pipe into the fitting. Test the operation of the check valve by blowing into the open end of the pipe, no air should escape out of the fitting. Then blow air through the fitting, you should feel air escape through the open end of the pipe.

#4. Assemble this end of the check valve by placing the washer in the fitting and the ball in the pipe. Then seat the pipe into the fitting. Test the operation of the check valve by blowing into the open end of the pipe, no air should escape out of the fitting. Then blow air through the fitting, you should feel air escape through the open end of the pipe.

#5. Seat the open end of the pipe into the other end of the fitting. Mark the fitting with an arrow that indicates the direction of water flow.

#5. Seat the open end of the pipe into the other end of the fitting. Mark the fitting with an arrow that indicates the direction of water flow.

Pump Body Materials

- 1 – 24” piece of 1¼” SCH40 PVC Pipe

- 1 – 26” piece of 1” SCH40 PVC Pipe

- 2 – 4” pieces of 1” SCH40 PVC Pipe

- 1 – 1¼” PVC slip-on coupling

- 1 – 1¼” PVC slip-on cap

- 1 – 1¼” to ¾” PVC FNPT fitting (I was unable to locate on of these fittings in my local hardware store so I used a 1 ¼” to 1” FNPT and a 1” MNPT to ¾” FNPT fittings to do the same job)

- 1 – ¾” FNPT x ¾” FNPT x ¾” FNPT PVC Tee

- 1 – ¾” NPTPVC coupling

- 1 – 1” PVC Plug

- 1 – 1” PVC slip-on tee

- 2 – 1” PVC slip-on caps

- 2 – Washers that slip on 1” pipe tightly

Pump Body Instructions

#1. Sand down the 1” pipe and layout two lines for the O-ring grooves. The dimensions of these lines or the spacing is not critical but should be around ¾” to 1” from the end and spaced about ¾” to 1” apart.

#1. Sand down the 1” pipe and layout two lines for the O-ring grooves. The dimensions of these lines or the spacing is not critical but should be around ¾” to 1” from the end and spaced about ¾” to 1” apart.

#2. Cut and file grooves along these lines for the O-rings to sit inside of. If you have access to a table saw, this process can be made much easier by building a jig to get a nice consistent depth.

#2. Cut and file grooves along these lines for the O-rings to sit inside of. If you have access to a table saw, this process can be made much easier by building a jig to get a nice consistent depth.

If you are like me and using hand tools, these grooves will be made by cutting, filing, and testing the fit.

Related: 5 Best Wood Cutting Tools

The goal is to make these grooves deep enough to seat the O-rings so that they provide a good seal between the pipes but also allow for ease of movement.

#3. Once the grooves are done, seat the O-rings and test-fit the 1” PVC inside of the 1 ¼” PVC. Use some petroleum jelly to lubricate. If you are happy with the fit install the 1” plug into the end closest to the O-rings.

#3. Once the grooves are done, seat the O-rings and test-fit the 1” PVC inside of the 1 ¼” PVC. Use some petroleum jelly to lubricate. If you are happy with the fit install the 1” plug into the end closest to the O-rings.

#4. Build a tee handle by installing the 1” slip-on tee on the end of the 1” pipe and the two 4” pieces of pipe into the open ends of the tee. Finish the handle by capping the ends with the 1” slip-on caps.

#5. Set the 1” pipe aside and grab the 1 ¼” pipe. Attach the 1 ¼” slip-on coupling on one end along with the 1 ¼” to ¾” FNPT fitting.

#5. Set the 1” pipe aside and grab the 1 ¼” pipe. Attach the 1 ¼” slip-on coupling on one end along with the 1 ¼” to ¾” FNPT fitting.

#6. Screw the ¾” NPT coupling into the pump body and screw on the ¾” FNPT x ¾” FNPT x ¾” FNPT tee.

#6. Screw the ¾” NPT coupling into the pump body and screw on the ¾” FNPT x ¾” FNPT x ¾” FNPT tee.

#7. Next drill a hole into the 1¼” slip-on cap large enough to allow the 1” pipe to easily slip through. I used a 1 3/8” bit to drill the hole.

Optional: If you have a washer or O-ring that will seat nicely in the cap while providing a seal between the cap and 1” pipe you can install it to add an extra seal)

Related: How to “Winterize” Your Pipes and Prevent Damage

#8. Lubricate the O-rings again with a generous amount of petroleum jelly and insert the 1” pipe into the pump body.

#8. Install the check valves keeping in mind the direction you want the water flow.

#9. Attach hoses or piping to the threaded ends of the check valves.

#9. Attach hoses or piping to the threaded ends of the check valves.

#10. Operate the pump just as you would a bicycle pump.

Even if you do not construct this build right now, knowing how to make a water pump like this is something that can and will come in handy when the lights go out.

This design can also be modified and experimented with to suit your needs and the same basic concept can be copied using other materials that you may have more ready access to.

You may also like:

An Ingenious Way to Catch Pigeons and Other Birds in Your Own Backyard

An Ingenious Way to Catch Pigeons and Other Birds in Your Own Backyard

The Awesome DIY Device That Turns Air Into Fresh Water! (Video)

How to Make A Cool Rocket Stove

10 Survival DIY Projects You Can Start on Your Property Right Now

Is there any way this can be modified to work with a well??

What Michael Major is teaching in this “Ask a Prepper” is how to make a gravity lift pump. Basically, the device reduces the air pressure inside the supply line, which allows atmospheric (“outside”) pressure to “push” water up the supply line until the inner and outer pressures are balanced or equilized. To see this, close one end of a clear tube about 33 feet long, fill it with water, invert the open end into a water-filled bucket, and hang the tube vertically. You will see the water level drop until it is balanced by the existing atmospheric pressure. Depending upon altitude above sea level, the water column will be about 32 feet. This length is known as a “gravity head.” Water wells using the gravity lift principle that are less than 32 feet deep will produce water. If the depth to water is more than 32 feet, a single-stage gravity lift pump won’t work. Multiple-stage gravity lift pumps, with check valves, have been designed and used, but I can’t find an online reference for you. When the depth to wate is greater than 32 feet, other lift methods are generally used. Low-tech solutions include buckets and the archimedes screw. The limitation imposed by gravity on lifting water from wells was why centrifugal pumps were invented. They use an external energy source to overcome the pull of gravity. Such pumps require an impeller submerged in the water. Depending on the power available to rotate the impeller, they increase the water pressure sufficient to reach heights substantially greater than 32 feet.

Interesting article. Worth saving info. No basement here and well water stands at 38 ft in a good year. I’ve seen it at around 45 ft after a few years of below nornal precipitation.

Very good idea. I have a small stream on n my property that I draw water out of with an electric pump for irrigation.

This would work when the power is out.

And no, I don’t care about any govt rules about taking water from a stream. I don’t subject myself to the propaganda issued by the pseudo rulers sitting in their ivory towers in DC. The stream is on my property, I own it snd the govt can pack sand.

Actually a question. How much lift can one expect. I have a well with water level at about 25′ thank you.

I believe the old pitcher pumps were only good for 32 Feet of well depth lift.

Do you know anyone who fabricates this kind of pump for sale??

Sportystoolshop.com has a hand pump for $44.95 that will pump fluids.

Harbor Freight used to carry them but a quick review of their website didn’t reveal one. They do have a barrel pump that could be very easily modified to pump water from some distance away with vinyl tubing.

My bad…I should have specified a manual pump for a 25ft deep Well. Is there one available out there ??

Robert: Amazon has a large selection of manual pumps that will lift water 25 feet. You just need to read the descriptions and select the one that fits your budget and needs. Tractor Supply has them listed as does one other company that I saw. I suspect almost any farm supply company stocks hand pumps that will life 25 feet. You just need to make sure your water level never falls below 32 feet because then you will need a different type of pump as outlined above.

If you have $500+ in loose change you can even by a solar driven pump for your well.

There are companies that make hand pumps for home wells. I am looking at one made out of SS.

https://www.bisonpumps.com/deep-well-hand-pump/

Neat little project, however isn’t there any manual commercial transfer or bilge pumps available ?

There are manual pumps sold at Home Depot. Yrs ago one was used on my boat. They are also good for a basement as they come with a 6ft hose. Real simple operation, drop hose in basement then pump up and down & water does away.

Dave: See my comment about Sportystoolshop.com

This is a awesome! I would probably need a hand making it. Thank for the info

I appreciate the time you took to write this out! Very good to know! Thank you!

You are very wrong to say all water is pumped into/out of homes today via electricity. I grew up Amish. Family still Amish and we have water without electricity. Besides generator pumps, there are windmill pumps and a device called a “Ram” to get water moving. There is also gravity fed, and solar … So, as you can see even in America we can live wonderfully without modern anything like electricity!

I have a small solar pump. I can run in in daytime to fill large containers then some containers use gravity and some j can pump with solar power. For home and garden i have 6, 330 gal caged and a 270 gallon caged container and several 55 gallon barrels available. I store,some water for home and critters use.

I could see using a pump like this for pumping from those contaibers.

Clergylady: There are barrel pumps specifically designed for 55 gallon barrels that do a very satisfactory job of piumping them almost dry go to Home Depot on line to see such pumps.

Ram Pump is what this reminded me of but I forgot the name until you mentioned it. Thanks! I saw it in a youtube video. Ram pump moving water hundreds of feet and Ibelieve uphill? Also no manual pumping. Once it’s primed it just runs on it’s own.

I have a well on my property and it is 26 feet deep, would this pump be able to lift water this high?

I saw this on you tube a few years ago. A guy that goes by the name “King of Random” did the video on how to build it.

Home where I’m staying this winter has large containers catching rain water then draining it away from the home. I’m looking at ways to use all that water for irrigation and that way returning it to the local water table while watering new trees and bushes I’ve been helping plant.

will this work for pumping water from water lines when theres a power failure?

Carol: If you are talking about water lines in your house, you can drain the water from the water lines in your house without using a pump.

Just put a receptacle under the lowest faucet in your house or the front hose bib after you have turned off the water at the water main or the shutoff valve by the front hose bib.

Turn on the water faucet furthest in your house from the front hose bib.

This assumes that the water enters your house at the front facing the street.

The purpose is to allow air into the line as it drains from the lowest faucet in the system.

This action is to drain water from the water pipes of the usual single or two story or higher home. If your question involves something more than that, I could only answer the question if I understood how your system was constructed.

Thanks Michael ! Great information and detail.

how many gallons per minute could this be expected to pump?

That would depend on the size of your family……….Calculate the swept volume of the pump stroke and estimate how many times you could work the pump in one minute times the volume and you would have the answer. {several teen aged sons helps) 🙂

Spike: I would estimate from the size of the pipes utilized in the pump design you could expect about a quarter to perhaps as much as a half a cup of water per stroke. How long it would take to pump a gallon depends on how fast you can stroke the pump and how long your muscles hold out. One cup is 8 ounces and a gallon is 128 ounces. There are 16 cups to a gallon.

Somebody commented that hydraulics limits this method of pumping to 32 feet, not correct, the limits are motive force available and the strength of the seals in the pump. This pump is the same style as the sucker rod pump on old windmills, a guy down the road from me has a 75 year old Aeromotor windmill that has been rebuilt once and lifts water 150 feet. The difference is instead of drawing water into the check valve assembly through a hose, the check valve assembly itself is immersed in a well. You could probably engineer a well pump with this construction method, maybe double up on the o rings. Also, when you’re in the store buying all the pvc fittings for this pump, go ahead and buy a couple of check valves, the pvc ones are only a couple of bucks and it will save you lots of trouble.

Now that I think about it, the sucker rod method is used in oil wells to lift fluids from 3 miles down…

Acrylic or rubber balls

You can NOT just walk into any store and ask for them.

I tried 3 diff hardware stored and 2 chain stores.

All I got was tuff luck. Look on Amazon.

So this is just another worthless article.

Especially since no part numbers were provided nor where to buy without boying online.

Crazy squirrel:

Try Home Depot or Lowe’s. Pretty sure they carry pvc pipe, pipe glue and the saws and stuff you need to put them together.

If they don’t have them, they might be able to tell you where you can find your balls, too.

In pumping water, keep in mind that water is heavy. The higher you lift it, the more energy is required. In constructing outside the pond filters for fish ponds one of the important factors one needs to consider is how high the filtering mechanism is above the pump in the pond. I used a 100 gallon per hour pump to lift the water approximately 6 feet. Was the output 100 gallons per hour? Absolutely not. But I needed that much energy to lift the water six feet in sufficient volume to keep the pond clean.

I have a 15 gallon per hour small pump for draining the wading pools that I use to catch rain water. I am only lifting the water one foot and don’t need to move the volume of water, so that works satisfactorily for me.

One reason the windmill worked well for pumping water was that it pumped small amounts of water as long as the wind blew. The water was pumped into a tank which provided the pressure needed to provide running water in the house.

If one drives on non-interstate roads through the midwest, traversing the numerous small towns, the one feature almost 100% of the towns have is the water tower. This is a large tank on a steel pedestal. By utilizing the tank storage method, the town is able to supply water during peak demands such as first thing in the morning or later in the evening when folks are taking showers. The level in the tank rises and falls depending upon demand.

The town is able to use a much smaller pump to fill the tank because it runs 24 hours a day, filling the tank during periods of low use and not keeping up with demand during periods of high use.

Most homes with a well have a pressure tank somewhere in the system. The pump runs when the water pressure drops below a certain level and shuts off when the tank is full. That is the system used to get water to the second or third floor.

I am certainly no hydrology expert, but with the information above, don’t expect the pump described in the article to pump water to supply your home. With sufficient effort it will fill a pail of water out of a creek or lake. It most assuredly will not lift water out of a well unless it is an artesian well only a few feet or perhaps even less before the surface of the ground. It will transfer water out of a tank to a bucket on the ground, making for a neater transfer of water.

If you want to examine a variety hand pumps with different purposes, you should go on line to Home Depot and put in hand pumps. They have more than 25 assorted pumps for sale.

I would estimate that the pump described in the article will transfer about 1/4 cup of water with each stroke. A cup of water is eight ounces. There are 640 ounces in a five gallon jug of water (or any other liquid)

For those on this list who have a well on your property and have concerns about not being able to obtain water from that well in the event of a long term electrical outage from any means, I would suggest you investigate well buckets on line. Well buckets are long narrow containers designed to manually withdraw water from your well. They work especially well for fairly shallow wells. If your well is 2,000 feet deep — well, I am afraid when the SHTF you are probably going to be just like me, looking for a water source.

I would also suggest reading up on well buckets so that you know what you are looking for.

There are some modern Stainless deep well hand pumps available but the actual pump is down below your expected low water level and has sections of stainless rod running down to the pump through sections of pipe to bring the water up.And YES, you will be lifting water from the current level of water in the well (your watter comes from the fixed check valve at the bottom of your pipe but you won’t feel any weight below water level in the pump. The one I bought was not available a couple months ago when a friend was asking and I don’t know if it will be (Being Water then probably .com ???) there ore others. Mine was over a thousand dollars for everything including 150 feet of rod and Pek sections with all fittings installed.

Another great article, thank you.

The comments section on these articles many times expand on the original topic in a big way and I really appreciate all the tips.

I’m having a hard time downloading the comments easily, any suggestions? No problem with the original article, just print and/or download as a pdf, it’s just the comments I’m trying to capture as well.

Anyone…. Would a steel ball work as well? I have a few old ones. Also some old glass marbles…

I was recently given an antique pitcher pump. if I can’t make it work on the well to pump 38 feet, then I find a way to use it on my 330 gallon caged water totes. I think this PVC pump, if made to work submerged, would do a great job. I have a simple hand operated pump on my 5 gallon water storage containers. even that will pump further that the depth of a 5 gallon water bottle with very little effort on my part.

I’m interested in anything that works manually. Always looking for alternative ways of accomplishing things.

I have several 55-gallon water storage drums and purchased a couple of stainless-steel hand pumps for them from walmart.com, and they work fine but I do not think they can lift

water very far. If interested, I searched walmart.com for “manual stainless steel water pump” and a lot of items are listed, so if you are looking for a hand pump for smaller lifts, here’s my search link:

manual stainless steel water pump