Solar is inarguably the most commonly chosen form of alternative power. It is relatively easy to install, costs nothing to operate (once installed) and works pretty much anywhere. There is also abundant sunlight available for conversion to electrical power.

The one problem with solar is its cost: installing enough solar panels on your home to power everything can cost upwards of $30,000.

Even so, solar is still the king for alternative power. Many preppers use it, as it allows going off-grid for your electrical power needs, without a major power plant or supplies of fuel. In a survival situation, it is probably the most reliable source of electrical power, especially when used in conjunction with a battery backup system.

While most people buy ready-made solar panels or even buy them from a solar contractor, this isn’t the most cost effective way of getting solar for your home. You’re much better off, cost wise, building your own; as they can be built for about half the cost of buying. All you need is some simple tools and the ability to solder.

An Important Bit of Theory

Before we try to build anything, we’d better understand what we need. A solar panel consists of a number of solar cells, connected and mounted together, so that they produce a useable output. This is all based on being able to charge 12 volt lead-acid batteries, much like the batteries that are used in a car.

In order to ensure that there is enough electrical power to charge 12 volt batteries, it is necessary to produce at least 14 volts. However, solar cells don’t always put out the maximum possible voltage. At times, they only put out 80% of their power, especially on cloudy or rainy days. So, it’s necessary to design the solar panels to produce even more voltage. Typically, they are built to provide 18 volts, 50% more than the nominal 12 volts of the batteries.

Each solar cell produces 0.5 volts, regardless of its size. Larger solar cells produce more watts of power, but they are still producing 0.5 volts. So, in order to get 18 volts, 36 of them have to be connected together. But how they are connected together is important.

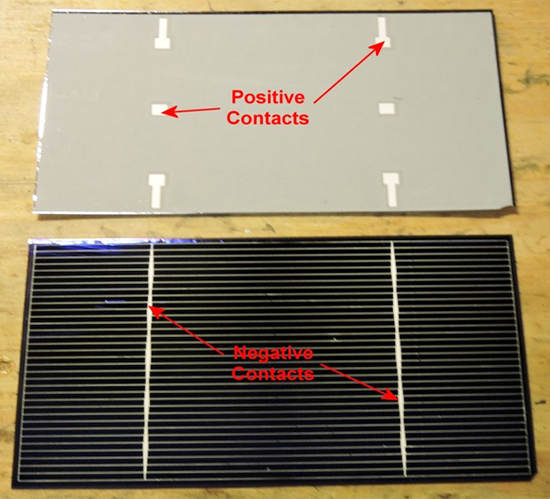

There are two different ways of connecting solar cells together, what is known as “in series” or “in parallel.” Like batteries, solar cells have a positive side and a negative side. The “front” side of the solar cell is blue and is the negative side. The “back” side is grey and is the positive.

The easiest way to understand the difference between series and parallel is to think of a batteries. A flashlight has the batteries installed in series, so that the positive end of one battery (the end with the nipple) is in contact with the negative end of the other battery (the flat end). This allows the current to flow from one battery to the next, adding the voltage together.

In this picture of a tactical flashlight, we see that the flashlight uses two CR-123A batteries. Since those are rated at 3.0 volts each, that means the batteries are providing 6.0 volts to the light. The same thing happens with solar cells, except that the cells are 0.5 volts each.

Related: How to Get Power Out of Your “Dead” Batteries

Connecting the batteries or solar cells in parallel, where all the positive ends are connected together and all the negative ends are connected together (separate of the positive ends) doesn’t affect the voltage. But it does increase the total wattage or current that the string of solar cells can produce. When connecting in parallel, the wattage of the cells is added, while the voltage stays the same.

So, a common size solar cell, such as 3″x 6″ will produce a consistent amount of current, regardless of the manufacturer. For the 3″x 6″ cells, this is 1.8 watts. When we hook two of these together in parallel, they produce 3.6 watts, but still only produce 0.5 volts.

Typically, solar panels are built by connecting enough solar cells together in series to make 18 volts. Then, those strings of solar cells are connected in parallel, adding the current together. Whether this is done in one solar panel with multiple strings in it, or by connecting various panels together in parallel depends on the size of the solar panels being used.

Soldering the Solar Cells

Solar cells can be purchased either “tabbed” or “untabbed.” This refers to whether or not they have lead wires already soldered to them. As soldering the lead wires to the cells is the hardest part of the project, there is an advantage in buying tabbed solar cells, but manufacturers do charge more for them.

Tabbing Solar Cells

The “tab” on solar cells is done with a special wire, known by the convenient name “tabbing wire.” This is a 2mm wide solid, flat, uninsulated wire. The wire is tinned, which means that it is coated in solder, making it easier to work with. Pieces of this wire must be soldered first to the negative side of the solar cells, “tabbing” them, and then to the positive side, stringing cells together.

Before soldering the tabbing wire to the cell, you must use a rosin flux on the contact area that was shown in the photo of the solar cells above. A single thin swipe of the pen over the contact area is sufficient.

![]()

Technically, it is not necessary to tin the contact area on the solar cell with solder, before soldering on the tabbing wire. But my personal experience has been that there isn’t enough solder on the pre-tinned tabbing wire to guarantee good contact; so I always tin mine first, applying the smallest amount of solder possible.

It is important to realize that solar cells are extremely fragile. They are made of paper thin glass, to which the photosensitive silicone has been applied. You can break one just by looking at it wrong, as the saying goes. So, they must be handled with extreme care. They will also break if overheated. I use a temperature controlled soldering iron, set to 700 degrees for soldering solar cells and I’ve never had a problem with breaking one from heat.

Related: What a Prepper Should Do Around The House

Once the contact area is tinned, the tabbing wire can be soldered on. Additional solder won’t be needed, as the solder on the wire and on the cell’s contact will be sufficient to make a good solder joint.

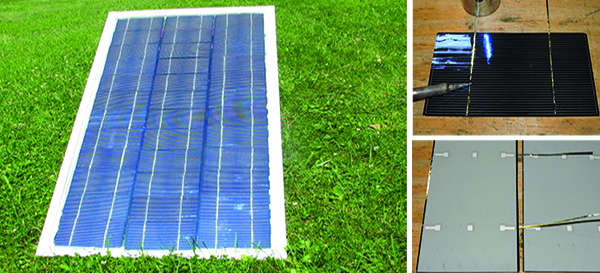

In the photo, I’ve laid a piece of tabbing wire, twice the width of the solar cell (six inches long) on the contact area of the negative side of the solar cell. The large silver thing in the top of the photo is a large socket, which I am using as a weight to hold the tabbing wire in place. I heat the tabbing wires, starting at the side near the weight and slowly dragging the soldering iron towards me. My speed is regulated by watching the puddle of melted solder on the surface of the tabbing wire. If I go too fast, it won’t melt and create that puddle. Notice how flat I am holding the soldering iron, so that it makes good contact with the tabbing wire.

It is highly useful to hold the near end of the tabbing wire down while soldering it. I normally do this, but with one hand on the soldering iron and the other holding the camera, I couldn’t. If you don’t have a soldering tool for holding it down, a small screwdriver will work.

Stringing Solar Cells

With all the solar cells tabbed, we’re ready to connect them together to make strings.

At this point, you need to decide how your solar panel is going to be configured. More than anything, this means how many cells you’re going to have in a row and how many total rows of cells you’re going to have in the panel. I usually use 12 cells in a row and three rows in a panel. However, you may choose to use a different configuration, due to available space or the size of the glass you have available to make the panels.

Just as we tinned the negative side of the solar cells, before tabbing them, we need to tin the pads on the positive (back) sides of the solar cells. So, apply some flux just to the pads and as little solder as you possibly can. Refer back to our first photo if you need to. The solder will not stick to the back side of the solar cells, anywhere but where the pads are.

Lay the cells face down, with the tabbing wires from one cell overlapping its neighbor. Align the tabbing wires with the pads on the back side of the solar cell and solder in place. Once again, you shouldn’t need to add any additional solder to make a good connection. However, you will need to hold the tabbing wire down onto the cell or it will lift when you remove the soldering iron.

As you can see from the photo, the space between individual cells is minimal. There’s only about 1/8 inch there. While this spacing is not critical, you don’t want to allow so much space that your string won’t fit in the panel. It can be helpful to use a yardstick or straight piece of scrap wood as an alignment guide, to ensure that your string of solar cells doesn’t end up with a curve in it.

Related: How to Build a Solar Oven

Mounting the Strings of Cells

If we are going to make three separate strings, they will have to be connected together to make one large string of 36 cells. However, it’s easier to mount the strings of cells first and then connect them together. Attempting to handle three strings of 12 cells that are connected together is just about a sure recipe for disaster.

You will need to have a backing board for the panel. I’ll talk in a minute about how that goes together with the rest of the case, but for now, suffice it to say that one is needed. This should be big enough for all tree strings of solar cells, with a minimum of 1/2 inch of space all the way around. One inch of space is even better, but many people try to keep their panels as small as possible.

The backing board can either be made of plywood or some sort of plastic. I like plastic, because it is weatherproof; but it is also more expensive. Plywood will work fine, if you seal all the edges and paint it well.

There are a number of fancy ways of attaching the individual solar cells to the backing board, but the simplest is also the best. That’s to put a small blob of silicone sealant right in the center of where each cell goes and set the cell on top of that. Since the cells have to be transferred as a string, place them on a piece of cardboard and slide them off the cardboard, onto the backing board. Press down lightly in the center of each to press it into the silicone sealant. Allow to dry.

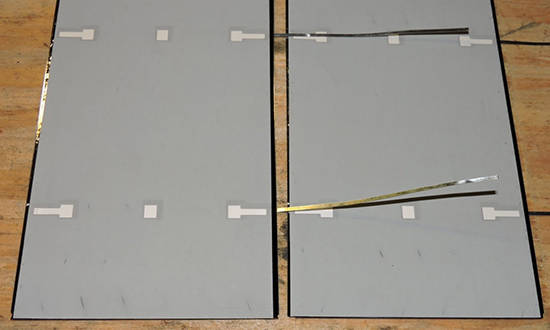

It is important to connect the strings together correctly. In the diagram above, we have three strings of 12 cells, making a total of 36 solar cells, for 18 volts. The middle string is laid backwards of the other two, allowing the positive end of the bottom string to be connected to the negative end of the middle string and the positive end of the middle string to be connected to the negative end of the top string. This makes for a string of serial solar cells 36 cells long.

Buss wire is used to connect the ends of the strings together. It looks a lot like tabbing wire, but is 5mm wide, rather than 2mm. the tabbing wire is soldered to it, completing the string. As you can see, there is a piece of buss wire sticking out from the negative end of the string and one sticking out from the positive end of the string. These will be used to connect the solar panel to other panels.

Enclosing the Solar Panel

We already have a backing plate to the solar panel; that’s what we mounted the solar cells to. All we need now is a glass face and a means of holding it together. This can be done with aluminum C channel or aluminum angle.

Start by attaching regular wires to the buss wires and passing them outside of the solar panel. That will either mean running one of the wires all the way around the inside of the solar panel or outside. Either way, you’ll want both wires to end up together.

Stick the glass to the front of the solar panel with 1/8″ thick double-sided foam tape. Make sure that it is at least 1/8″ thick, so that it doesn’t crush the solar cells, or you might end up breaking several cells. The double-sided foam should go all the way around the panel, along the edge, sealing the glass to the panel without any gaps.

Once sealed, put a thin skin of silicone sealant around the edge of the panel, sealing the glass, double-sided foam and plywood backer board together.

The only real attachment the parts of the panel need is the foam tape used to hold the glass to the backing board and the silicone sealant used to hold everything to the aluminum angle, as well as seal all the edges and make it waterproof. It’s important that the whole assembly is waterproof, as any moisture that gets into it will condensate on the inside of the glass, reducing the amount of light that reaches the solar cells.

You can mount the solar panels any way you would like. Just be sure to point them true south. This is usually different than magnetic south by a few degrees. To find out what the difference between the two is for the area in which you live, search for “magnetic declination” on the internet.

The angle they should be mounted at depends on the longitude of your home. To calculate the angle:

- Multiply the latitude by 0.87, if your latitude is below 25 degrees

- Multiply the latitude by 0.76, plus 3.1 degrees, if your latitude is above 25 degrees

The answer to this calculation tells you the angle off of vertical for your installation.

To finish off the installation, connect all the panels together, in parallel, and then connect them to a charge controller for a battery backup. The output of the batteries can then be run through a voltage inverter and connected to your home to provide power.

You may also like:

10 Faraday Cages that You Can Make at Home

Do You Make These Fatal Mistakes In A Crisis? (Video)

EMP Myths and Facts. What’s BS and What’s True?

H2O Dynamo – The Awesome Device That Turns Air Into Fresh Water! (Video)

What is the best (looking at both cost and quality) have you found for the bulk solar cells?

Very useful article!! Thank You Al

Where can I buy individual cells?

instead of breakable glass over the cells, how about plexiglass or shatter-resistant or bullet-proof. this would help protect the cells during storms when shtf and goes flying around too. plastic would be lighter as well. could not a small hole be drilled somewhere to let out condensation, then sealed again.

Glass is cheapest. Plexiglass is not cheapest. Bulletproof? Good lord. Expensive and overbuilt. We’re looking to save money and resources.

This article does not mention and EMP attack or a Corinal mass ejection from the Sun. The backer board and glass cover provides some protection but the wires connecting the panels are not protected from an EMP. Some re-thinking is needed here for use by a prepper. It would be bad news to do all that work for power, just to loose it in an EMP attack.

Thanks for the article. I had not thought about making them myself. Great idea. I have been soldering for years on things and it doesnt seem ti difficult. Thanks again.

On the DIY tutorials, could you begin with a list of tools, parts, etc.? Thanks

I cannot see any of the videos and some of the articles, because of ,”clickbank”. They ruin everything.