The majority of today’s homes heat water with either electricity or natural gas. When we remove these from the equation, we discover the reality of how much energy it takes to heat water.

Placing a pot of water over a fire is a good method for heating some water, and you should absolutely do so whenever possible, but there is an easier DIY alternative.

How Does This Water Heater Work?

The off-grid water heater I detail here requires a wood-burning stove, and we are going to harness the heat energy that radiates off of it to warm up the water.

Related: Easy DIY Water Purification System For Under $20

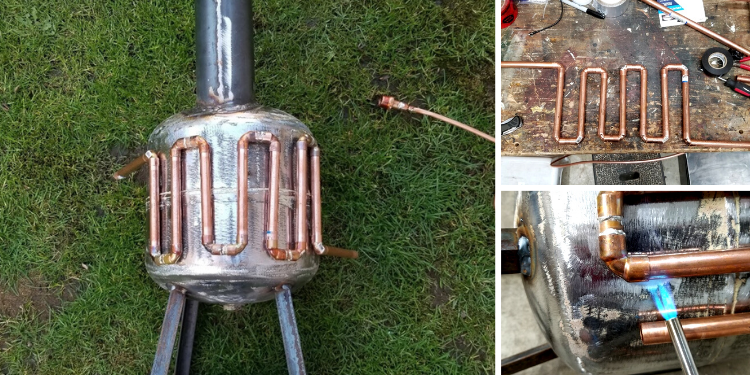

All that is needed is to build a run of copper pipe along the sides of your wood stove through which cold water will enter, and hot water will exit.

Since copper is such an amazing conductor of electricity and heat, the pipe will become heated and transfer that heat to the water inside. What this creates is an ‘on-demand’ hot water system.

The Wood Stove

Building your wood stove is not difficult as long as you have access to a welding machine, angle grinder, and a supply of steel.

I made a woodstove for this project out of an empty 20-pound propane tank that I had lying around.

Related: How to Make Your Own Solar Stove

If you do not have access to a welding machine, you can purchase wood stoves online.

Building a Wood Stove From a 20 Pound Propane Tank

Turning a propane tank into a wood stove is not difficult and requires only a few easily obtained materials to build.

Unfortunately, there is no way to accomplish this build without using a welding machine, angle grinder, and an oxy/acetylene cutting torch or plasma cutter.

These tools also require some skill to use, and many safety considerations need to be taken.

Instructions

1. Empty the propane cylinder and thoroughly clean it inside and out. Be sure that all the liquid propane is removed before proceeding further.

2. Remove the rings at the top and bottom and remove all the paint from the tank’s exterior.

3. Lay out and cut the opening for the door. Make the opening large enough to load wood into the stove comfortably.

4. Save the piece that you cut out to fabricate the door.

5. Secure this piece to the rest of the woodstove with a section of piano hinge. Add a handle at the same time.

6. Fabricate a base from the 1x1x1/8 angle. I chose to make it 12 inches square.

7. Cut four legs on a slight angle so that they will slope upwards to join with the cylinder.

8. Weld the base frame onto the stove body.

9. Cut a hole in the top to accommodate the four-inch stove pipe.

10. Slide the stovepipe into the hole and weld it in place.

11. Cut some expanded metal to the inside diameter of the wood stove and place it inside the stove.

The Heater

How you run the pipe will depend on your woodstove’s shape, but the basic principles are the same.

What we are trying to do is snake the pipe along the side of the woodstove to get as much pipe as possible exposed to the heat. We can do this in two ways.

We can use pipe elbows to snake the pipe along the side of the stove, or we can use a coil of copper pipe and wrap it in a tight coil around the chimney of the woodstove.

The difference between these two methods is that there will be less heat from the chimney, and therefore the water will not be as hot.

Related: Disinfect Huge Amounts Of Water With This Common Household Item

However, since using the woodstove sides create hotter water, the risk of too much pressure is ever-present and needs to be accounted for.

Materials For A Side Mounted Heater

• Copper Pipe

• Copper 90-degree elbows

• NPT copper fittings

Instructions

1. Measure the height of the woodstove side that you want to place the heater on while figuring out how many vertical runs of pipe you will use.

2. Measure the height of the elbows and how far the pipe will fit inside of them. The difference between these dimensions multiplied by two is the length that will be subtracted from the heater’s height to figure out the cut size.

3. Cut enough small lengths of pipe to join the 90-degree elbows together. At the same time, cut the straight sections.

4. Cut two six-inch lengths of pipe for the inlet and outlet.

5. Trial fit all the components together.

6. Solder the 90-degree elbows together to form the 180 degree turns in the pipe run.

7. Layout the heater on the stove to check the fit.

8. Solder the joints together. Don’t forget to install the fittings on the inlet and outlet so you can connect the water supply.

9. Drill holes for bolts to hang the heater on the side of the stove.

10. Install bolts that are long enough to hang the heater on.

11. Insert the bolts into the holes and secure them on the inside of the stove with a nut.

12. If needed, use a piece of metal strapping to hold secure it only on one end so it can be easily lifted out of the way to remove or install the heater.

Using the Water Heater

There are a few options when it comes to operating this water heater.

The first is to use it as an on-demand type of system where you draw the coil’s water as needed to get hot water.

The problem is that there will be a buildup of pressure within the system, and you will need to have a pressure relief valve in the system.

My preference is to keep the coils removable so that you can quickly and simply install the heater on the stove when needed and remove it when not in use.

Harnessing the heat that a wood-burning stove emits is a great use of this radiant energy to provide us with heated water.

Being able to get hot water on demand is one of those comforts that will make a grid-down scenario a little bit more comfortable.

You may also like:

Why Do Government Officials Want To Ban Ham Radio? It’s Already Begun In California

Why Do Government Officials Want To Ban Ham Radio? It’s Already Begun In California

This Homemade Device Can Power Up Your Entire House 7 Days in a Row (Video)

So you have to have a fire going all the time to have hot water on demand.

Ya cool idea, but not for me.

Having an, on going fire to have hot water on demand is a waste of wood and time.

Where is and how is the water being delivered to the unit. ?

Remember this is a grid down sinerio.

I believe that it will be much much harder to live when the SHTF. We can’t imagine.

Just look at Ukraine. Not easy surviving in a war zone.

Think in your mind. Can I really survive.

Thank you…

Scenario.

Sorry just couldn’t help myself. My #2 pet peeve.

We have a 20 gallon water tank on the back of our wood-stove… It Keeps near boiling hot water ready to go whenever its needed. I would say for the time and effort you put into making some project is cool but not really worth it.

It might be cool for something out-doors like i use for the maple syrup boiling…..

While I’m glad the article touches on the hazards of creating a steam EXPLOSION with this homemade uncontrolled heat source convection water heater, I am hopeful the folks will do some more research about how dry bubbles in such a coil or a bunch of 90 degree couplings can create a superheated bit ‘O steam and probable explosion.

That the coiled around the chimney would give you cooler water is amusing given heat rises and I’ve seen near white hot chimneys before.

Open cycle water heating like the side water heaters seen on old style cook stoves work well and like a Tea Pot or boiling pot of water on top cannot generate those superheated explosion issues.

Do be aware unlike your faucet hot water there is NO Regulation so your chances to JOIN the thousands of Scalded Homesteaders Club is very high.

Where red lives a solar hot water system with a well insulated tank will give him pretty hot water for his morning shave, dishwashing and such. Such systems can be modified to act as a preheater for a proper wood fired hot water system WITH a REAL Safety Valve OR my personal fav the tea kettle style pop off.

When SHTF don’t join the scalded folks just figuring out ONE MORE thing as stuff gets weird around them. Look around to YouTube and such for proven systems. The child you save might be your own.

I have to agree with you Michael. I think the coils around the heat exhaust would be the idea and most safe option here. I like the concept and the built has a lot going for it. But that pressure built up is a key considerations. Steam tends not to like to many 90 degree turns.

The only thing I see wrong is that the stove heat might melt the solder. Someone will eventually overfuel the stove and things will get red and then your pipes will fall apart. (Of course, depends upon the melting point of your solder or braze). This might occur if someone runs it with no water in the pipe, leaves the door open, etc… If there is any pressure in the lines, this may occur spectacularly. It would be a much better idea to bend a jointless coil around the stove or stovepipe, my opinion.

A pressure relief valve, as someone else suggested, is also a safety plus.

That was meant to be *constructive* criticism and observation, hope it came across that way. I do think it’s an awesome idea.

A must have for the steam punk enthusiast prepper

Ill go with a solar heater instead

We had this arrangement in the house where I lived as a small boy. It was a coal stove I have mentioned before called a bucket-a-day because it took a coal bucket of pea coal a day to create hot water for a household. It was my job when we switched from the main furnace that provided heat and hot water in the winter to thebucket-a-day in the summer. The main furnace had a heat exchanger located inside the furnace. The water jacket was built into the b a d. Both systems fed a pressure boiler that had a safety valve in it.

Every hot water system needs a pressure relief valve that vents the hot water and/or steam to the outside.

Failure to install a vented pressure relief system will burst the water line and a high pressure jet of scalding water will ensue.

Once again, I have first hand knowledge about the phenomenon. One of my print shops had a laundromat in the adjoining space. The hot water system sprung a leak and flooded my plant, ruining a lot of paper and printing orders to be picked up or delivered.

I now suspect the reason the system sprung the leak is because when initially installed the pressure relief system was not installed .

A week after we had gotten everything cleaned up and the owner of the laundromat had a new water heater installed, the system exploded again because the plumber (?) failed to install a pressure relief valve. The hot water heater, as you can imagine, in a laundromat is not your household 40 or 50 gallon hot water heater. It is a large boiler with a very large heat chamber to make for faster recovery than one needs in a family home.

So at night when no one was using the system, it once again let go. This time the hot water jet blasted a hole through four layers of drywall, through both walls in my shop, flooding not only my shop but the exercise salon next door.

It must have been a truly impressive sight seeing scalding hot water blasting through the dry wall like a water cannon.

So my tale should reinforce the prior comments about hot water systems needing a pressure relief valve. Go to where your hot water heater is located and look at the tank. Somewhere near the top of the tank you will see what looks like a hose bib with a little lever on top. That is your pressure relief valve. It should be vented to the outside. If it is not, some day your garage or wherever the hot water heater is located will be flooded due to the pressure relief valve doing it’s job and releasing hot water from the overpressure in your hot water tank. They have been known to explode where the installation has been faulty.

To borrow from my favorite gun-loving poet, Lizzy Barrett Browning, WOW … how many bad ideas in this piece above? Lemme count the ways. This piece is bad to the depth and breadth and height my soul can reach when thinking of ways to heat water. For the ends of being and post shtf harken far better alternatives than burning endlessly amd pressurizing explosively. I loath this idea to the level of everyday nonsense … of wasting resources, funds and time. Of printing more money to lower inflation and cutting off pipelines to lower gas prices. Most quiet need, by sun and candle-light we shall heat our H²O before embarking in the folley of this wastefully wistful contraption of well-meaning wishes. I deplore thee freely, as men strive for right and warmth and cleanliness, not to waste thy time. I speak to thee purely and turn from such bêtise as above.

Very clever. Thanks for the literary post.

Many years ago I built and installed a hot water coil in my wood furnace. Plumbed it into a 30 gallon hot water heater tank which was mounted behind and higher than the furnace.Cool water from the bottom of the tank fed the lower end of the coil and the hot water from the top fed back to the top of the tank so continuosly heating and circulating. See THERMO SIPHON CIRCULATION. The over pressure/ temperature valve fed into a line that went to an old wringer washing machine tub. This warm overflow water was used to water the horses, They REALLY like a warm drink on a sub zero morning.

This system provided all of our hot water for a three female household, long showers anyone? We always tried to either run a load of laundry or the dishwasher last thing at night to minimise overnight runoff.

A little time and effort and mostly salvage parts saved many hundred gallons of LP GAS.

I would greatly appreciate any photos/drawings/sketches for this setup. I tend to do better with illustrations and this would work well for a current project in my no-electricity barn.

You system sounds like a VERY good one. It would sure be great if you could produce and article showing with pictures how yours was created and how it works.

Stove design needs combustion air supply controll and if this design does not set outside, I am afraid it might smoke back into the house quite badly.

Using a 30 or 40 p0und LP bottle would give height enough to wind the heating coil several time around the stove body above the firebox door eliminating the right angle fittings and potential steam traps and flow restrictions.

Would make a simpler build.

Somewhere I have plans for a rocket stove which would adapt well to a water heater of this type and make it much more fuel efficient.

I like sweating copper pipe but it would be a lot more efficient to use copper pipe that comes in a roll and just wrap the heat source. If you wanted a gallon of hot water out of this system you would need to heat 100 feet of 1/2 inch pipe, or you would have to improvise an insulated storage tank. The hot water system you end up using will be dictated by needs and resources. We used to do a lot of 7-10 day wilderness trips, fuel and water were at a premium. Discovered two people could meet all their daily sanitation needs with a wash cloth and a couple inches of water heated up in a saucepan. Or a dip in a lake or river. Water is such an excellent solvent you don’t really need soap to stay fresh. Washing dishes, half inch of very hot water in a saucepan and a sponge. 17 months since my wife was paralyzed by West Nile Virus, she is just now strong enough to bathe herself. You wouldn’t believe how clean and refreshed I can get a bedridden patient with a washcloth, a quart of warm water, and some high dollar bath gel.

Just about everybody can scrounge enough ‘junk’ to make a rocket stove, the most efficient way you can use carbon to heat water, boil filtered water to make it safe, boil water for coffee, heat it for soups and teas and sanitation. Shoot, with no power failures and a mild winter I burned half a cord of good oak firewood in our small fireplace just for fun. Hate to think of the labor of fueling everything with wood.

We burn 6 to 10 Cords of wood in a normal winter …..

This system would be great if you have the skills to troubleshoot it and to install it, but for a more limited skill-set such as mine, I would suggest one or two large clam pots with a spigot at the bottom. Good quality large ones run $75 and up unless you find them on sale or at a flea market, etc. The costs would probably be no more than the cost of buying copper piping and something to use as a reservoir. The advantage to this method is that you are still using the heat from the wood stove, but all you need to do is clean and fill the pot and put it on the back burner. (Or you can fill the pot on the stove if it’s too heavy.)

You can also use cheaper pots, so long as you plan on their eventually needing to be replaced. Since they are cooking pots, you can also use this hot water to cook with or make a hot drink. Depending on the type of piping you use for the heater in the article, this may not be advisable.

Yes, it does require manual refills and transferring the hot water to your dish pan or wash basin, and unless you rig up a gravity shower with a refillable water reservoir you’re stuck hauling water to a tub for a full body wash, but if you’re off grid you’re going to have to get used to a different way of life.

You can also get the type of solar hot water heaters that are used for camping if you want a shower, and I saw a clever set up on YouTube several years ago that used plastic water carboys painted black and set in a sunny window to warm up to be used to shower. Unless the weather is overcast or extremely cold, this would probably work year round and doesn’t require any thing other than passive solar heat.

Still, a great article for the diy-er and a lot of food for thought.

Clam pot is a misnomer, but that is what they’re called around here. This is what I was thinking about.

https://www.brewinternational.com/premium-5-gallon-stainless-steel-stock-pot-with-weldless-ball-valve/

There are others out there, but this has a good picture.

JH: I am happy for you that your wife is recovering somewhat from her bout with the West Nile virus. I know what a struggle it has been as for about six years my wife has wandered down the misty paths leading deeper and deeper into the fogged state called dementia. The only bright spot is her gentle loving nature that drew me to her 66 years ago still shines through the fog that now clouds her mind. Due to widely geographical separated family, I am her sole care giver and this site and a couple others are my contact with the outside world, as you guessed sometime back. I can appreciate your struggle. This certainly isn’t how I anticipated growing old together.

*has never built a still

It works, I wrapped copper coil about three feet up the stovepipe, routed lines in the flooring and installed a small aquarium pump and pressure release valve. A warm feeling floor in winter is awesome.

Nice read.

Just a thought while heating water for washing cooking etc, through a system like this, has anyone thought of putting a turbine within the system in order to generate electricity to charge batteries?

Of course, Marty Rainey did it, lol!

BEFORE CUTTING INTO A PROPANE TANK fill it with water to the very top. Failing to due so could cause residual gas mixed with air to EXPLODE!!!!! Do not leave even the smallest air pocket.

When we lost utilities after a hurricane hit north Florida. I set a couple gallons of water (1 gal jugs) in the sun to heat. These were used by my grandsons for personal cleanup.