Abundant clean water is widely recognized as one of the top survival priorities, with most survival instructors saying that you need at least a gallon per person per day for drinking and cooking.

The most common means of purifying water is by using a filter but there are other options like:

– boiling the water – it’s hard to purify enough water to meet a family or group’s survival needs and you would still have to filter the particles;

– chemical purification (such as using chlorine) – requires that you have enough of a stock of chlorine to last through the crisis.

And so it seems the bio-filter is your best option in a crisis. Bio-filters can easily be made out of readily available materials. They essentially duplicate the same process that a water treatment plant uses to purify water, but on a much smaller scale. This multi-stage process removes dissolved and suspended solids, as well as almost all waterborne pathogens.

The pathogens are the important part of water filtration. These pathogens are bacteria and protozoa which can infect our digestive systems, causing diarrhea and dehydration. Left long enough, they can cause death by dehydration. More than anything, they are the ingredient hiding in most fresh water sources, which can make us ill. So, that has to be our focus.

How a Bio-Filter Works

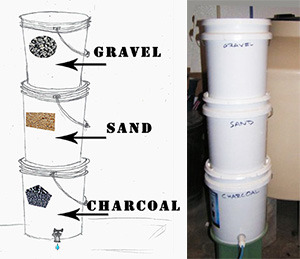

A bio-filter is a three stage filter, allowing each stage to provide a finer level of filtration.

The first level consists of gravel and is there to remove larger solids, such as leaves, twigs, bugs and even pieces of feces that might be in the water.

The first level consists of gravel and is there to remove larger solids, such as leaves, twigs, bugs and even pieces of feces that might be in the water.- The second layer is sand, which will remove floating and dissolved particles of solids as the water passes through it.

- At this point, all that is left to be a problem is the microscopic pathogens, which are reduced by over 99 percent by the final layer, that of activated charcoal.

Activated charcoal is an amazing material. It is charcoal or carbon, in which the pores have been opened, expanding the surface area. The surface area of activated charcoal is a minimum of 500 square meters per gram and can be three times that much. That’s what makes it so effective. The large surface area traps the pathogens, preventing them from passing through.

Activated charcoal can be purchased commercially, but it can also be made. The easiest way to make it is to treat charcoal with a hot acid or a strong base. This will cause the pores in the charcoal to open up. Commercially, the wood is usually impregnated with acid, a base or salt, by soaking the wood in it, before burning. Then, as the wood burns, the pores are opened.

Building a Bio-Filter

There are a number of ways that you can build your own bio-filter. Some people try to make them in soda bottles or other small containers. The problem with this is that the filtration isn’t as thorough as it is for larger filters. More than anything, you want a thick layer of activated charcoal, so that it can remove the pathogens from the water. So, I recommend building it in three 5-gallon buckets.

To build your own bio-filter, you’ll need:

- 50 pound bag of sand

- 50 pound bag of pea gravel

- 25 pound bag of activated charcoal or carbon (volume will be about equal to the sand and gravel)

- Four 5-gallon buckets

- Screening (for replacing a torn window screen)

- Epoxy

- 3 ceramic wall tiles (like you would use in a bathroom shower)

- An electric drill with 1″ and 2″ hole saws

- Scissors

- Something to use for a stand, such as two cinder blocks standing on their end

By using three buckets, we are able to use plenty of material to ensure that the bio-filter will work effectively. This will also ensure that the filter will work for a long time, rather than becoming clogged up with garbage quickly. Basically, the bigger the filter, the longer it can filter effectively and the better a job it can do of filtering.

Prepare the Buckets

You are going to stack the three buckets up, with each of them taking on one part of the filtration process. To make this possible, we need to make a path for the water to pass from one bucket to the next. So, using the electric drill and the 1″hole saw, drill a hole in the bottom of three of the buckets. Then change over to the 2″ hole saw and drill a hole in the lids of two of the buckets. Leave the lid for the top bucket alone.

You are going to stack the three buckets up, with each of them taking on one part of the filtration process. To make this possible, we need to make a path for the water to pass from one bucket to the next. So, using the electric drill and the 1″hole saw, drill a hole in the bottom of three of the buckets. Then change over to the 2″ hole saw and drill a hole in the lids of two of the buckets. Leave the lid for the top bucket alone.

Cut a couple of 3″ squares of the screening material for each of the buckets. We’re going to use more than one to give it added strength. Epoxy these in place, on the inside of the buckets, so that they cover the 1″ holes you just drilled. You may need to use something to hold the screening down, while the epoxy is curing.

Place the ceramic tiles over the screening, shiny side up. You can use a small amount of epoxy in the corners

Prepare the Filtering Media

The activated charcoal needs to be crushed, if it isn’t already. You don’t need it to be powder, but you do need it to be small pieces, a couple of millimeters across. If you buy activated charcoal, it might already come this way, or in little sticks that are 2mm (0.08 inches) in diameter and 1cm long (0.4 inches).

The activated charcoal needs to be crushed, if it isn’t already. You don’t need it to be powder, but you do need it to be small pieces, a couple of millimeters across. If you buy activated charcoal, it might already come this way, or in little sticks that are 2mm (0.08 inches) in diameter and 1cm long (0.4 inches).

Start by rinsing all three m filter medias (gravel, sand and activated charcoal). The sand and gravel will have dust and dirt in them and the activated charcoal will have charcoal dust in it. This needs to be rinsed out. Using the extra bucket, rinse five to ten pounds at a time, filling the bucket with water, swishing the media around in it and pouring the water out. Repeat this process over and over, until the water no longer becomes cloudy.

This is the boring part of the project, but have patience. If you don’t get all the dirt and dust out now, you’ll have to dump the first however many gallons of water from the filter, until it starts coming out clear.

As each batch of filter media is cleaned, put it in the appropriate bucket, gravel in one, sand in another and activated charcoal in a third, until all of it has been cleaned.

Final Assembly and Use

Put the lids on the charcoal and sand buckets, snapping them into place. Place the two cinder blocks on end, as far apart as you can, while still allowing the opposite edges of a bucket to sit on them. Your bucket that contains the activated charcoal needs to be placed on the cinder blocks. Wiggle the bucket and blocks to ensure that they are stable.

Place the sand bucket on top of the activated charcoal bucket, being sure to center it. Check again to ensure that everything is stable. Finally, put the gravel bucket on top of the sand bucket to top off the stack. Don’t snap the lid onto the gravel bucket, just allow it to sit loosely to keep out dust and dirt.

You can put two to three gallons of water in the filter at one time, pouring it into the top (gravel) bucket and then capping it. I use a one gallon plastic pitcher, as a larger container would be a bit awkward to raise that high up above the ground. Place a container on the ground, between the cinder blocks, to capture the water as it is filtered through.

It should take about 1/2 hour for the water to percolate through the layers of the filter and come out the bottom. Don’t be surprised if the first several gallons come out murky. That’s just dust that you didn’t manage to rinse off. Keep filtering water and that will stop quickly. Then you’ll be able to safely drink the water that has been filtered through your bio-filter.

You may also like:

Why You Should Put Plastic Forks In Your Vegetable Garden

Why You Should Put Plastic Forks In Your Vegetable Garden

The Awesome DIY Device That Turns Air Into Fresh Water (Video)

How To Make Your Chickens Lay More Eggs

9 Hiding Spots In Your House Where Looters Always Look First

Can I just ask for clarification, is this American gallons? As apparently US and UK gallons are different. A 5 gallon bucket holds roughly 25 litres of water. Just wanted to check before gathering everything for a weekend project

US gallons (3.8 liters) but it doesn’t matter; it works with any bucket as long as it’s over (let’s say) 2-3 gallons so you can have a decent amount of charcoal and sand to purify the water.

Here is a video from Doomdays Preppers. it seems that they also made the 3 bucket filter: https://www.youtube.com/watch?v=aYYcg18RXLs

… but please rinse the sand and the charcoal very well. the water seems a little bit murky there.

About how many gallons will this filter before you need to replace?

Absolutely no way to know for sure.

Approx. 6,000 gallons… (Depending on your water source)

So… Could be less, could be more… Just depends on your water source.

This is info I found, through months of research.

I tested these tyoes3 of filters as well, over the years. They work absolutely GREAT!

For about what you will spend or less putting together the supplies here to build just one you could buy a sawyer filter system at Walmart. It will make a lot more water that is safer by a huge margin.

You cannot just make this on the fly. It requires forethought and planing. Why not just take $25 to the store and get a proper filter or two and truly be prepared.

You must me just the buckets, sand and gravel…add in 25# of activated carbon and you take this little project into the $150 range.

Hi you can do that, but this is a good thing to know too!

This is the system to have if you had to bug out with family or firends and are in the wilderness by a stream. The Sawyer systems are more for personal use.

I’ve purchased 4 high quality manufactured 2-gallon capacity systems, give’em as gifts to siblings. It’s just prudent to be able and ready to improvise. If you live in CA, for instance, you get ZERO minutes’ warning of a quake. Filter “straws” have some utility, but they are very limited capacity/lifespan.

Often you can get food grade buckets from restaurants, much cheaper than new.

Sandwich shops buy pickles in bulk, and you can ask. Some have started selling their used buckets for $5 That’s still a lot less than new buckets and new lids, which are almost always sold separately.

Commercial filters for drinking water are a good solution for making safer water in small quantities.

But there is also a need for larger quantities of relatively clean water for other purposes like washing and sanitation. The sand filter system should be able to manage that. Surface water can get pretty skanky, and having some method of removing most of the skank is what is needed for those non-potable water needs.

For some extra clarification, when you rinse the filtering media, do you need to use already-filtered water? Obviously that would be better, but is it possible post-issue to construct and use the bio-filter as described without needing filtered water (a classic chicken and egg problem)?

I need to see the results of testing this to determine to what percent which pathogens and noxious chemicals are removed. I know bio-filters are used in Africa but havent seen the reliability testing on this.—-I like berkey black filters and Polar pur (can still get but expensive) a Conquest International’s home water distillation for use with alternate energy sources….and a good solid pressure cooker (boiling alone doesnt take down all the pathogens) jand then filter–

If its living in the water and harmful to you then yes, boiling kills it dead…

http://cid.oxfordjournals.org/content/34/3/355.full

Sford is spot on with the costs here as well…g’head, price 25 pounds of activated carbon. Then google several different filters that are less than just the carbon and a boat load easier to use.

Since you probably dont just have 25 pounds of carbon laying around why not buy a couple proven filters that are going to last a lot longer and do a much better job at keeping you from getting the squirts!

https://www.ebay.com/sch/i.html?LH_CAds=&_ex_kw=&_fpos=&_fspt=1&_mPrRngCbx=1&_nkw=25+lbs+activated+carbon&_sacat=&_sadis=&_sop=12&_udhi=&_udlo=&_fosrp=1

Should you boil water only do this once as heavy metal will accumulate not evaporated

The store bought filters are great but you still need to know how to make a bio filter. In a long term survival situation the store bought filter will eventually surpass its limits of filtering. Then you will need to know a way to filter water. You always need a back up plan for everything.

Sure, everything has its limits. Since I cited Sawyer above lets just go with that one and its limit of 1,000,000 gallons. Now I know a million is probably not realistic but lest just say you get a quarter of that service life and lets put it in real use terms. A family of 5 that consumes, oh, lets say 10 gallons a day on average over a year…that is 18250 gallons needed. Lets go ahead and just round that up to 25000 gallons. If my math is correct a quarter of a million is 250,000 and if you divide that by 25000 you have 10 years before you have a worry about needing a new one…or in this case, cracking the seal on the one you haven’t opened yet since you could buy about five for the cost of this project.

…so yeah, eventually you wont be able to filter water with a store bought filter.

In real life, people are only getting HUNDREDS of gallons upon device failure. I realize you are probably just spitballing, but you fail to mention that.

Correct, when SHTF, you might be stuck some where unexpected, knowing how to make the filter and knowing how to make the charcoal, even inactived, could be a life saver.

I have a filter in my BOB, but, if you get searched and someone takes your filter at the end of a gun, are they going to take your buckets, sand, pebbles, and charcoal too? Not likely at all, tell people I am a mason, tools of the trade.

If we go back to the stone age, how long before no gas, batteries, and water filters. Better to practice in ideal conditions and learn now, then fail under trying times.

I heat entirely by wood, have a sawmill, 37 ton log splitter, electric log splitter, etc. I still practice splitting by hand, have cut down trees with two man saws, and started by stove twice this year with my Swedish Steel.

It is about being prepared and being able to survive and thrive in any circumstance, not just about the money.

My son and I used the Sayer filters on a backpacking trip one time. Our water source for the hike was a mountain river. We had heavy rain one night, which increased flow in the river and created a lot of suspended solids. Both of our filters were clogged by the end of the next day. Luckily I had a UV light to kill viruses; but that didn’t filter out any of the suspended material. On that trip the life of the filters were less than 20 gallons, starting brand new.

I think a lot of people just do not get the idea of “emergency” and “survival”.

My question is this…Can ordinary charcoal be used if activated charcoal is not available? Never made activated charcoal and not sure how. Have made lots of charcoal

If push comes to shove, you can use diluted urine to activate your charcoal, but it does take a couple weeks of soaking. You should research this while the means are available. I have a (livestock supplement) tub full of activated charcoal I need to spread out to dry & then bag up. Though my intent for this is the garden, with the rains that have further diluted the soak over winter, I’m comfortable just rinsing it well to use for a project like this. Several instructional videos out there, though on how to make it with lemon juice (would take a lot for 25 lbs) or other acid.

Correct, when SHTF, you might be stuck some where unexpected, knowing how to make the filter and knowing how to make the charcoal, even inactived, could be a life saver.

I have a filter in my BOB, but, if you get searched and someone takes your filter at the end of a gun, are they going to take your buckets, sand, pebbles, and charcoal too? Not likely at all, tell people I am a mason, tools of the trade.

If we go back to the stone age, how long before no gas, batteries, and water filters. Better to practice in ideal conditions and learn now, then fail under trying times.

I heat entirely by wood, have a sawmill, 37 ton log splitter, electric log splitter, etc. I still practice splitting by hand, have cut down trees with two man saws, and started by stove twice this year with my Swedish Steel.

It is about being prepared and being able to survive and thrive in any circumstance, not just about the money.

A Sawyer Mini says it can filter 100,000 US gallons. Using a gallon a day, that’s about 273 years. Even if it only does half that, it still outlasts me. Just sayin’

I live in coal country. So would the coal I could dig up work or does it have to be a specific kind?

http://generalcarbon.com/facts-about-activated-carbon/activated-carbon-faq/ Sounds like you’d have to do quite a bit of modification to get the carbon’s pores to open up, Nana.

No, plain old coal aint it, not even close. Activated carbon is what this recipe calls for and 25# of it is quite expensive.

Activated charcoal is made from burning biomass, quenching the fire when it good & burned but not ash, then “activating” with an acid or base additive. Guidance is available from multiple sources online.

If you use a forth barrel on the top with small holes that would trickle slowly into the gravel bucket you wouldn’t have to stand there and add a little at a time. and you would know how much clean water you would get. They are getting kinda tall might want to tie or zip tie them to a pole in case you have a boo boo. Or Murphy comes to help.

I just watched this video on how to make your own activated charcoal. I am sure if you scale it up so you can make a lot of it

https://www.youtube.com/watch?v=lN0fT1Uvcsw

This is not how to make a bio-sand filter.You have no Bio-Zone!

https://www.youtube.com/watch?v=6bqYI1Z68jM

Activated carbon can be made at home safely by a 7 year old. A 25% solution on standard table salt, NaCl, is all you need.

http://library.queensu.ca/ojs/index.php/ijsle/article/viewFile/4244/4344

But I have to question how this is a bio filter. There is no bio-zone. I guess you could add a bio-zone by adding a tube to the output value and raising it to the appropriate water level.

Greycon,

The activated carbon acts as a carbon source and medium upon which non pathogenic bacteria grow and adsorb the excess nutrients, eg NO3, PO$ etc and cause deposition of heavy metals that come out of solution due to bacteriological (biological) activity.

The activated carbon is therefore the bio-zone.

Consider using an upward filter. Same principle but inlet at bottom: Gravel, pea gravel. course sand, activated carbon (or even ashes, cotton cloth with a small layer of sand on top.

leave room above top layer of sand. about 2-3″ above the top layer, put the outlet with a tap. letting the water rise above the outlet.

Nest a large container on top of the filter container and tap in place, especially to stop contamination. and connect a pipe from the side/bottom of the top container to the bottom/inlet of the filter container.

Put your untreated water (stream well etc) into the top container and then use treated water from tap as necessary.

This works in African villages without any western services.

In the short term, a commercially made water filtering system will be more efficient and easier to use than this system. In the event of a major CME or EMP power grid shutdown, the effects will be measured in years rather than day or months. Eventually everything that is commercially made will stop working. Even the plastic buckets will not be available. What you will wind up using will either be metal pails or wooden buckets pictured as the collection bucket. That is when you will be using this system to purify your water. Or else you will have learned how to make beer and/or wine and will drink watered beer or wine in place of plain water. In medieval times the servants or slaves were made to drink the water source first. If they survived, then it was okay to drink the water from that source. Often times though, the hitherto safe water became contaminated with the resulting illnesses and deaths associated with waterborne pathogens.

Will this filter work if the government starts poisoning the water? yeah there is people that will do that.

If you want to get rid of flouride, you would need to add a bone char filter into this.

As pointed out, this is proven technology. Bacteria acualy will grow on all thee media, gravel, sand and charcoal. The bacteria is responsible for displacing and eliminating most of the pathogens.

The sand and gravel can be cleaned, if necisaraly, and the charcoal dried and despised of. As the charcoal will also absorb many heavy metals and chemicals one should not use it for fuel or biochar on your garden.

As to making activated charcoal, wood ash will provide a lye solution (use of a mild base), and then proceed with charcoal making with the soaked and dried wood.

As one can see sourcing, procesing and assembling the materials takes a bit, so a secondary method for short term survival is a good idea.

As pointed out by the OP, the bottom loading system works much better, as it is not a flow threw system. The water is held in the filter containers, allowing the bacteria to work on the resolved organic material, organic chemicals and pathogins, and allowing the charcoal more time to absorb other chemical contaminants.

I certainly am not saying to use known contaminated sources of water ( or should I say heavily contaminated) but it is sertainly safer than nothing, probably better than what comes out your tap, and obtainable in a situation where your brain, hands and time are more useful than your credit card.

if you are currently using well water, there should be no need for all this trouble, except you may want to boil the wall water. If your pump stops due to electric outage, make sure you have a generator that will run the pump. Make sure your generator can run on propane if gas is scarce.

mmmmm,,, how much fuel are you going to have on hand????? for a few years???

Not all wells are the same. I have an artesian well that is 85 feet deep and filled with particles and sulphur to the point that it is not even suitable for a shower. I have to pull the toilet valve out and clean some kind of algae build-up at least twice a month.

This is mainly talking about wtshtf. You will not be able to buy this stuff, you will have to make it. Everything will be gone from the market places in probably 2 weeks. So no bio filters or food especially no potable water.

People used plain lump charcoal for generations. And while this does filter water right from the start, it becomes more effective after a couple weeks of use when microbes populate the filter thus making it a bio filter.

I don’t see anyone talking about the use of Ionic Colloidal Silver. With just a few minutes of learning Colloidal Silver can be made right on the spot. If you don’t want to make your own silver generator they can be bought. Google for information on it. Silver has been used as a disinfectant almost since the beginning of time. It is effective and the bad bugs can not become resistant to it. The electric power source for making Ionic Colloidal Silver can be 4 of the little 9 Volt batteries, or a DC power supply that will produce 32 Volts. I actually made a power source out of 3 solar cells that produce 12 Volts each. They are wired in series to produce 36 Volts but in direct sunlight they will generate as much as 48 volts. All this is contained in a 3 ring binder note book. Now after saying all this be aware and understand this. What ever the power source is that you use the “current” must be limited to no more than 1 milliamp. This is done by putting a current limiter in the negative wire. Google for how to make a Colloidal Silver Generator. Every prepper should know about Ionic Colloidal Silver, its antibiotic and disinfectant properties and how to make your own. I have been doing it for over 5 years now.

How many milliamp per gallon

The sketches show some type of spigot in the bottom bucket to drain the filtered water into the catch container. Any idea where someone can purchase one of these? It would be a lot easier having a spigot if for example your catch container is full and needs to be transferred to another container in the middle of filtering. When the SHTF, every drop of water would be like gold.

Search for outdoor faucet or “sillcock”. My rain barrel kits came with threaded “sillcocks” to tighten against the drain hole, which fit the standard garden hose.

I know they come on vegetable rinse barrels, for commercial kitchens. So, those are actually food safe.

An excellent and natural alternative to chlorine for the same uses is GSE (Grapefruit Seed Extract). Clense wounds, prevent infections, purify water, etc., and it is very compact to carry or pack in your BOB, first aid kit, or vehicle. https://appliedhealth.com/benefits-of-grapefruit-seed-extract/ Note that some supliers have been found to include traces of benzethonium chloride so check your source that it does not, though even if it does, you need only exclude the “internal uses”. It is still very valuable for disenfecting cookware, counter tops, cloting, etc.

I am setting this up and not cheap. About $200. for charcoal- Amazon. I am interested in on going maintenance. Will it be effective to rinse and sun dry the materials periodically or will they need to be replaced. Is there a better way to “freshen” the charcoal?

I would like to know the answer to that too.

I have a Sawyer and chemical purification in my go bag. Home has a variety of of filters and chemical options.

Thank you for this idea,

I am replicating this for a science fair project and I was wondering if I could use a smaller bucket and use less materials. I was thinking about a 2 gallon bucket and using only 1/5 of the materials to build this. The problem was the activated charcoal because it was so expensive. Please let me know if you think 1/5 of the materials is safe to use. (Don’t worry, I won’t drink it!)

yes

Wao, this is really coal. I guess it will serve to filter water for my animals . Been battling to get a suitable filter to clean the river water close by

I am confused about water draining from the sand bucket into the activated charcoal bucket. How do you prevent the sand draining down as the water is flowing down?

this is really helpful to me because in my tech class I am building a water filter with a couple other classmates. we are to come up with a design that could be used in third world countries with resources that they have lying around and yes this could be used in a good handful of poor countries. All I am asking is permission to use your design.

Thanks. – Tony

I want to make this for my parents in my home country!!!

Use activated charcoal from coconut shells. These are used in commercial water remediation systems worldwide. ( This is reusable in a pinch by just blow torching it).

This removes the elements that are harmful in water, such as arsenic, lead, etc. It is not a medium for removing bacteria. It can, but no guarantee’s, there can be channels within the carbon. Put a UV system at the end for about $100, and this will work for 10-12 people/day. Yes this would require power. I have 50 lbs of activated carbon in my garage for a similar system. I worked in this industry, water/wastewater for most my life.

Commercial fishery products companies have a lot of nice water cleaning products, and UV lights.

I also have a ceramic filter system for use by fewer people.

How do you use the ceramic wall tiles.

They go in the bottom of the bucket shiny side up. Used to keep the filter in the buckets so the don’t come out the holes

I do not understand the purpose of the ceramic tiles over the screening unless it is just for holding the screen in place until epoxy has cured? Do you remove tiles after words ?

Looking into something like this to filter rain water for my chickens. Using a set up similar to this then having the water flow into a storage container. So my thoughts are a large collection container for initial gathering then a stair step of buckets like this to filter it, and a large storage tank at the end. Where we have planned to put the chicken coop does not have easy access to water and in research I have found just plain rainwater collection would not be ideal for the animals. Do you think this could work?

What kind of epoxy? Does it have to be food grade?

I’m going to sort of disagree with you there. Is this a wet or dry filter system? In eather case Sand will not lower the TDS of the water, what it will do is create a nice anaerobic place for bacteria to grow unless it is dried after every use, Also that would be like pouring mixed kool-aid in and expecting clean water out, AC will not remove parasites eather, to kill parasites you need a high powered ultraviolet light or a secondary chemical treatment. The AC will help with turbidity only. I love the 3 bucket idea, but it’s too small,for this design to work you need constant flow as well as dwell time for the AC to polish, I hope no one is betting their life on this design or the many other cookie cutter diy filters like it.

After reading several of the comments, I agree that there needs to be additional clarification on the building process. There is no mention of needing lids in the building materials. There is no pictures on the size of holes, one inch hole then 3 inch square? What the heck? What does the tile do? What size? Make it easier for us first timers!

Thanks for the very informative article, Rich.

I learned of this article from Ron Foster’s book Crossroads of Chaos with a reference back here.

I’ve pretty much decided to do things a lot differently than spending tons of money on buying things when I can make them at home such as in making activated charcoal,etc.

This is great for purifying water whether in a grid up situation or grid down situation.

If one is concerned about bacteria growing within the buckets as some have commented, it would be a bit of work but not that difficult to rinse and dry all mediums I imagine.

Thanks so much for the information.

I’m concerned about the epoxy. I don’t think I want my water coming in contact 3 times with epoxy, dried or not.

Also, has anyone ever tested the water from these to determine exactly if they do or don’t work? And what about after 3 months or so of use? Does it retain the ability to purify water? What about the question of the sand just filtering through with the water….

Too many issues with this and not enough answers.

I do agree that in a total dire straights scenario, this is better than nothing, but also agree that you will need to have these items already as you won’t be able to get them after said emergency.